COBOP – Coal Blend Optimizer VR

The coal blending will impact in the plant performance, coke quality and costs. Decisions about coal blending must be based on a number of competing objectives involving plant performance, emissions, coal blend quality, coke quality and cost.

The coke quality obtained is related to the coal blend. The model to be implemented has the following objectives:

- Predict the coal blend and the coke quality, constrain blend and coke quality properties

- Help to the process Engineer in decision making for the coal’s purchasing

- Minimize expected (mean) cost of coal blending accomplishing with coke quality

- Minimize the standard deviation of coal blending cost

- Evaluate a new coal or selection of a least-cost coal blend for a plant.

Model Economical Benefits

COBOP models will help to estimate coal blend and coke properties and will allow to the user to observe how the coal properties and coal’s blending ratio will react in the blend quality, the coke quality and production parameters. This will become a practical tool for the process engineer.

The object of the model is not only to estimate coal blend and coke properties but also to find a blend that could accomplish with blend/ coke quality and production minimizing the coal blend cost to significant levels.

The main economical savings in the process could be obtained by three main sources:

- Coal Blend Cost Optimization

- Blend Consumption Reduction

- These two combined effects.

Modules

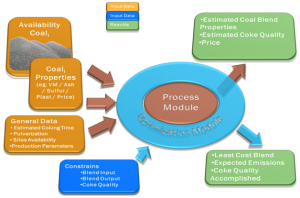

The Coal Blend Optimization system (COBOP) is built with four main modules:

- Process Model Module

- Optimization Module

- Statistical Module

- Calibration Module

We have a strategic plan. It’s called doing things.