CIRA Infrared Analytics – Ladle / EAF / LMF

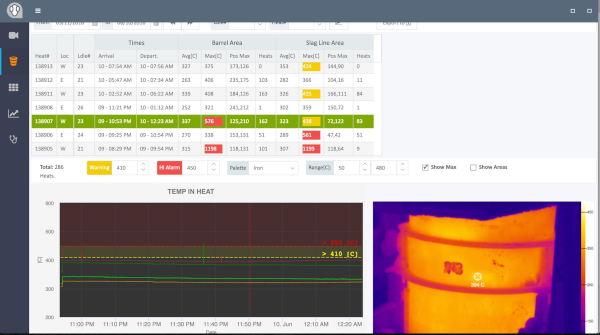

System Interface Overview

- Live Video: Real time video from cameras, alarms view for current HEAT.

- Ladle History: Temperature trending graph for all HEATS, the screen allows to filter by HEAT#, TIME, LADLE#

- Ladle Image History: Images for most important events of every HEAT (start/end, maximum temperature reached in slag line/barrel)

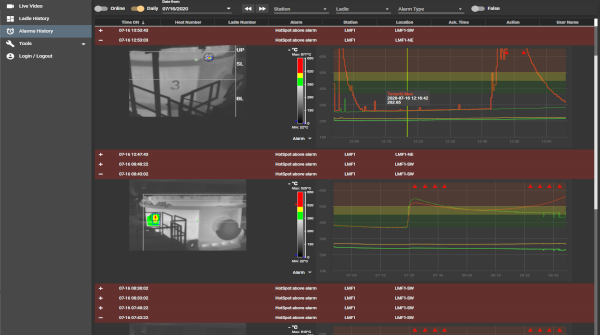

- Alarms Report: Alarms detected in every HEAT, the screen allows to filter by HEAT#, TIME, LADLE#

- Maintenance screens:

-SCADA Trendings: Graph view for all tags

-System Status: Processes status and diagnostics.

Software Overview – UX

- User Management – Viewer | Operator | Supervisor Profile

- Live video feed in HTML5

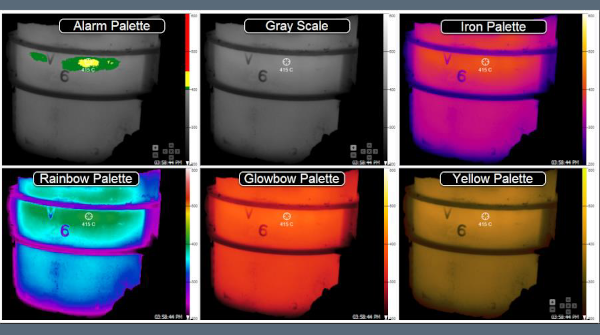

- Real Time Visualization

- ROI’s- Region Of interest – Tools for manual analysis

- Alarms – Hot Spot Detection (Plain Colored indication for easy visualization)

- Reports and Historical Data

CIRA for Ladles automatically grabs thermal images processes the images, triggers warnings or alarms and stores all the information to be consumed by any client connected to the existing intranet.

CIRA is the only hot spot detection system that contains AI models to identify and classify spills, splashes, avoiding false alarms and reporting real hot spots, as well as developing hot spots in time.

We have a strategic plan. It’s called doing things.